Sustainable manufacturing is the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. Digital Solutions and Assets like APC also need similar attention. With prudent maintenance and meticulous upkeep of APC controllers, any problems which may manifest in due time can be mitigated effectively.

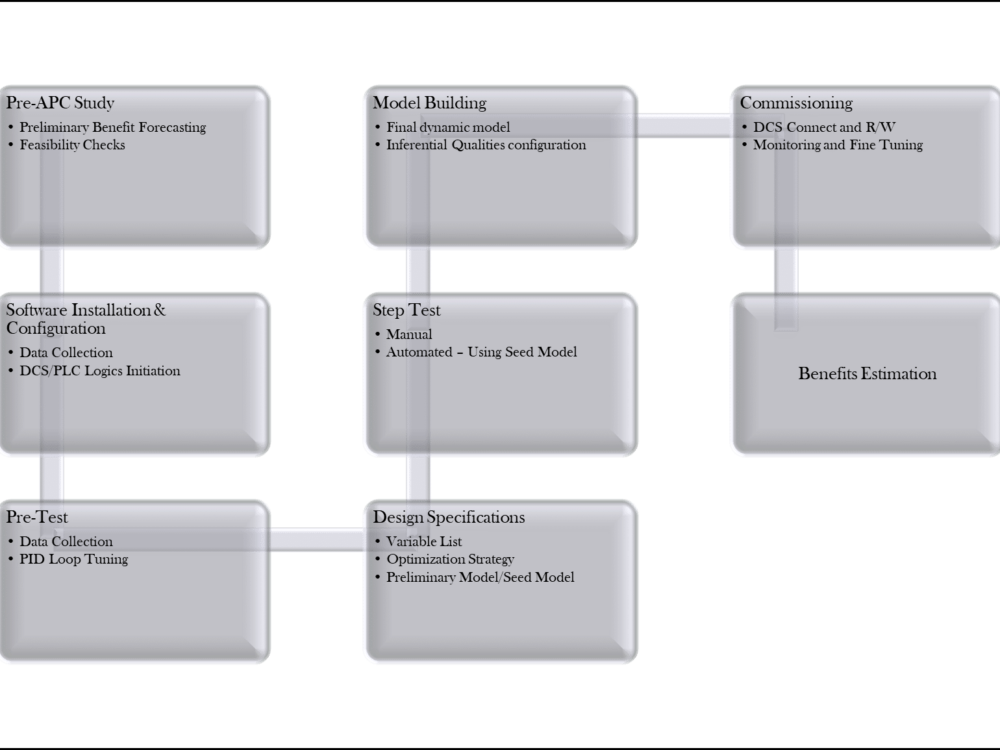

To understand the causes of gradual deterioration of APC and chalk out a value sustenance strategy, it is necessary to examine a typical APC implementation workflow.

PID Tuning and Design Specifications are fundamental building blocks to a good APC. Subsequent steps are dependent on the completeness and preciseness of the design specifications. The APC controller can only be robust with good PID Tuning.

At the start of the APC program, all optimization opportunities are identified and objectified to its associated process parameters. These parameters are benchmarked as Pre-APC levels. Digitally capturing the data by historization enables comparison of Pre-APC and Post-APC levels and to reflect on the quantum of change, which are indeed the Benefits of an APC.

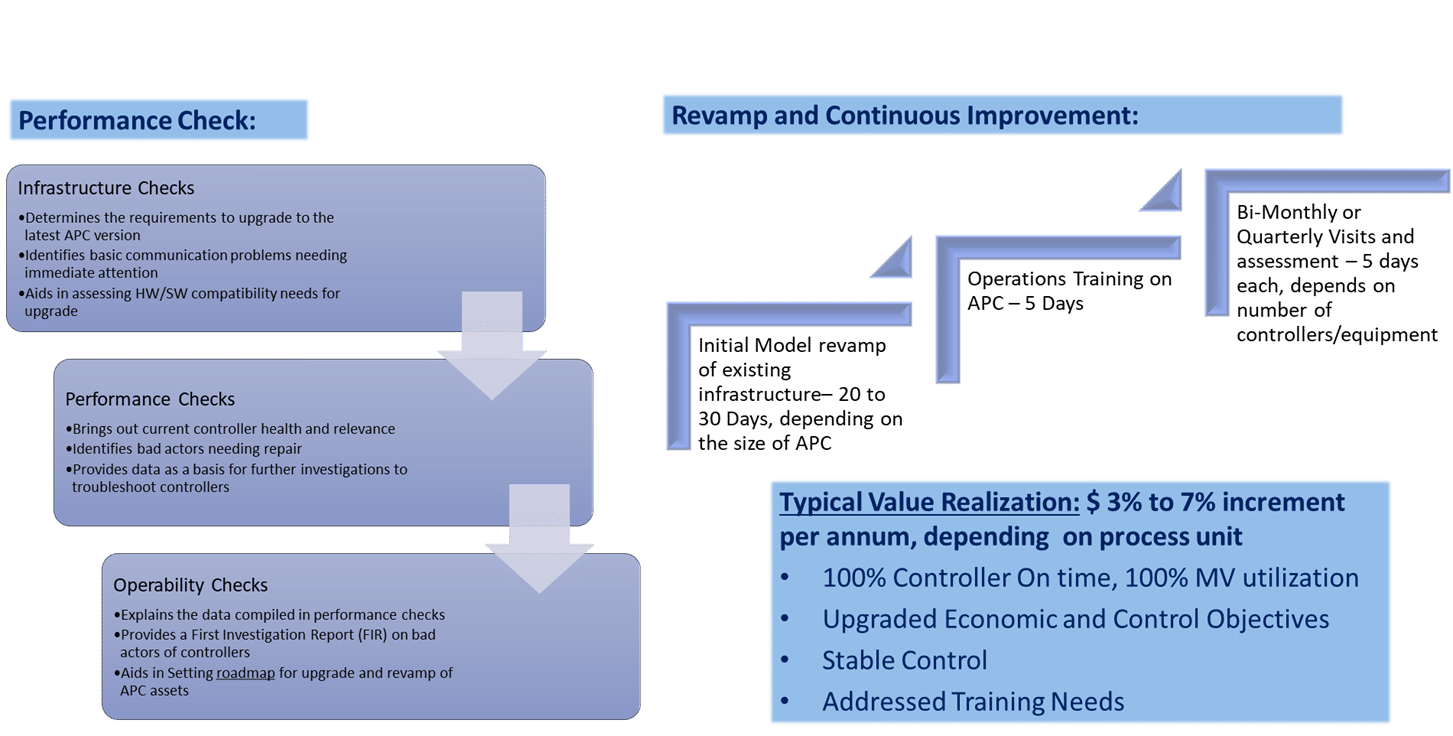

The quantum of Benefits must be always preserved. But in due course of time, owing to deterioration and underutilization of APC controllers, the Benefits may reduce, and in some cases the controller might be operating at a region far worse than the Pre-APC benchmarked numbers.

It is thus clear that the performance of a controller directly influences the quantum of Benefits. With a structured continuous maintenance, the point of deterioration can be prolonged infinitely. On the contrary such a program can yield more Benefits from the same controller.

To structure a maintenance program, it is crucial to identify the root cause of all bottlenecks the operators are facing with the controller. But it is easier said than done as quite often operators cannot speak the same vocabulary as the APC practitioner. They simply cannot explain what the problem can be.

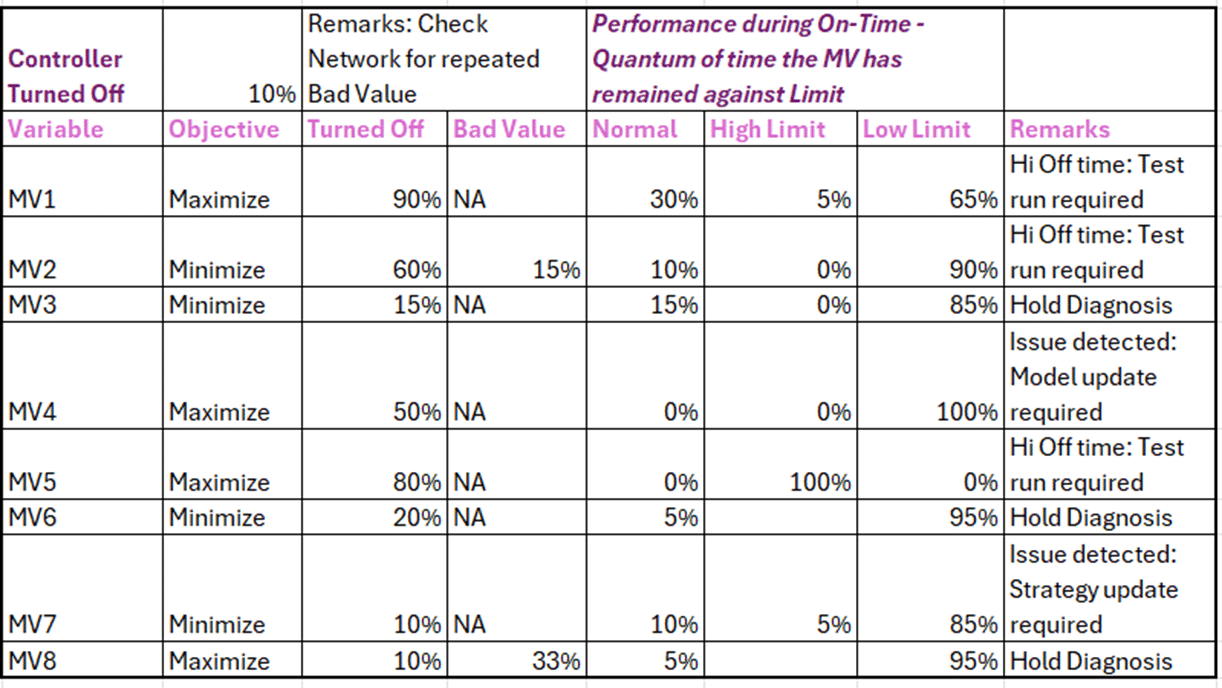

The only sure way to deal with such a situation is to examine data. A mapping of all Manipulated Variables (MV) and the Set Point profile for a period of a few months will provide the right prospective.

An APC controller can perform badly due to (i) Infrastructure and network issues (ii)Intrinsic flaw in design (iii)Repurposing deployed APC controller for objectives, which are fundamentally not designed for (iv)Process infidelity (v)Skill deficiency of Operators. A lot of these issues can be identified by studying the MV operating profiles.

Infrastructure and network issues manifest as “Bad Value” of the variable. A robust network will ensure data streams continuously. While the following two issues would require design modifications, the other issues need consistent and rigorous engineering efforts.

A process plant would have turned off the APC simply because an APC is not proving benefits. An APC practitioner would convince the operators switch on to facilitate a test run of the failed controllers. A mismatch in the MV movements against the economic objectives indicates a design flaw. A complete overhaul of control strategy should be the call for action.

Sometimes, it might so happen that over time, the market has changed the manufacturing scenario. The design objectives of the APC might not be economically viable anymore. Operators tend to continue use the APC but with new objectives, the controller would not cope up with the expectations. A design change with re-modelling and modification to variables is called for.

A process plant undergoes many changes over time. Since an APC is designed based on process responses, the model will not hold good for a changed process behavior. Process infidelity can be identified by studying MV operating history. A deviation of predicted values from the actual measurement indicates a requirement for re-stepping and re-modelling. These efforts must be timely so that Benefits are preserved.

Continuous training and workshops will ensure the upskilling of operators and greater APC utility.