We combine cutting-edge design, rigorous simulation, and manufacturing expertise to deliver market-ready, optimized products faster and more reliably.

Translating market needs and user feedback into feasible, innovative product concepts and industrial design sketches.

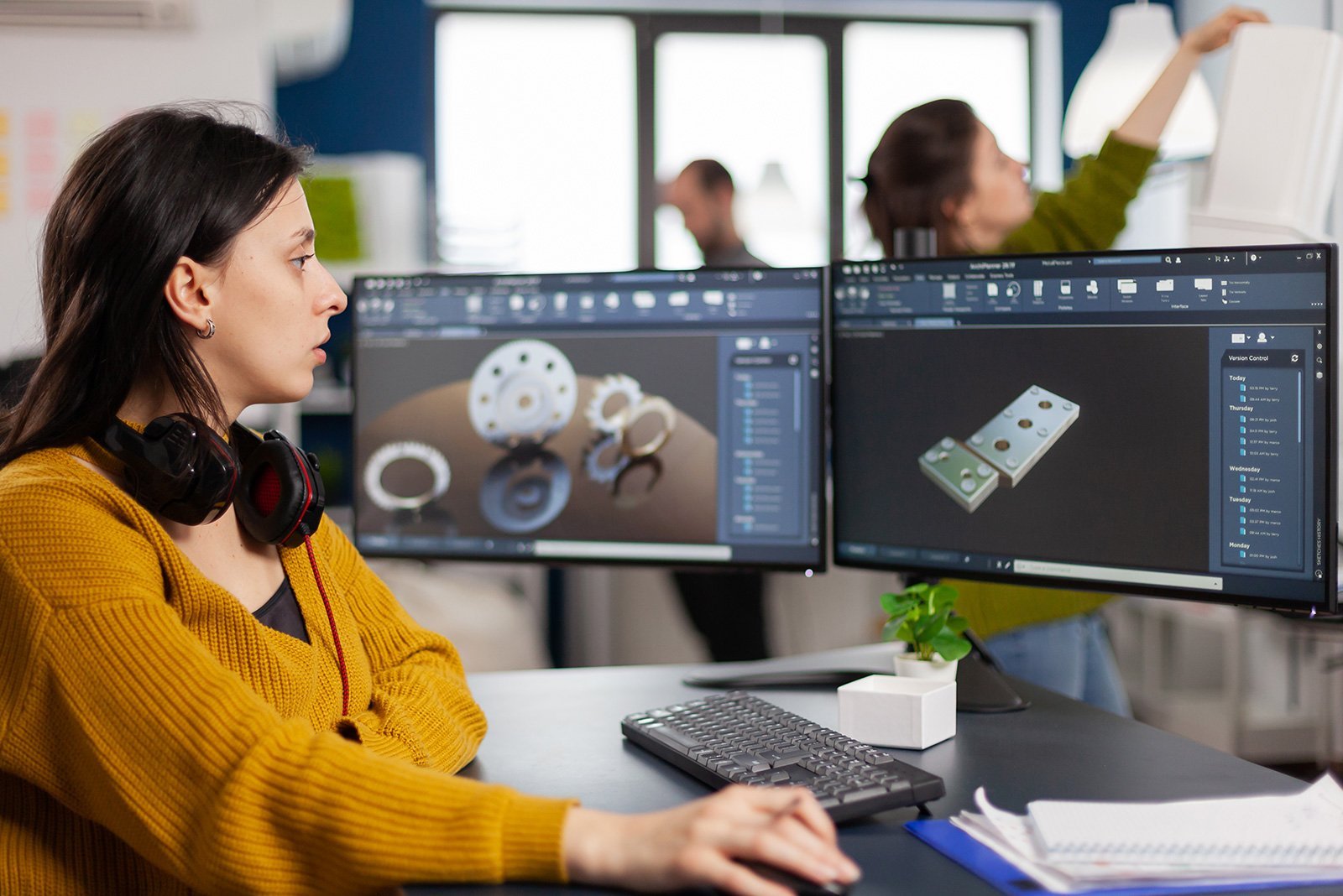

Creating production-ready CAD models, detailed drawings, and complete Bill of Materials (BOM) for fabrication.

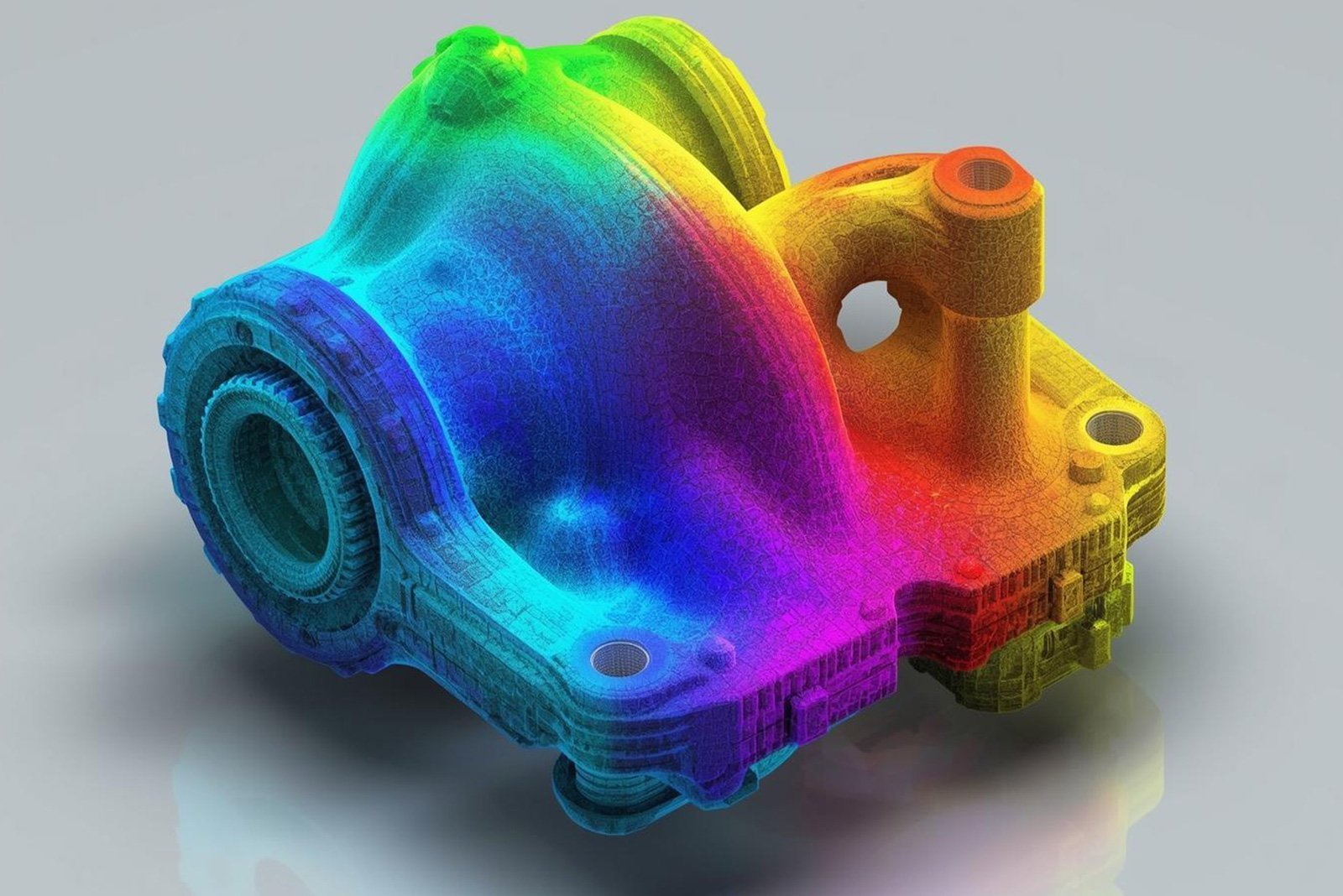

Virtual testing for structural integrity, thermal performance, vibration, and fluid flow before physical prototyping.

Optimizing the design to reduce part count, simplify assembly, and ensure cost-effective, high-volume production.

Managing rapid prototyping (3D printing, CNC) and setting up design verification testing (DVT) and qualification processes.

Systematic analysis of existing products to reduce material and labor costs while maintaining or improving performance and quality.

Our team is proficient across all major industry-standard platforms, including SolidWorks, Autodesk Inventor, PTC Creo, and CATIA. We are also skilled in managing data translation and model conversion between these different software environments.

Simulation replaces costly and time-consuming physical prototype testing with virtual analysis. By rapidly testing design changes against stress, heat, and flow resistance in the digital realm, we can validate and optimize the design in hours, drastically reducing the number of physical prototypes required and shortening the design cycle.

Yes. Our Design for Manufacturing (DFM) expertise focuses heavily on this. Whether moving from casting to sheet metal fabrication, or preparing a design for advanced additive manufacturing, we will redesign components and assemblies to ensure optimal performance, minimum cost, and high yield for the chosen process.

Driving down costs and accelerating time-to-market for content creation and testing.

Protecting your organization from model misuse, data leakage, and compliance failure.

Creating autonomous systems that perform multi-step, decision-driven business processes.

Grounding LLMs in secure, real-time enterprise data to eliminate speculation and error.

Tailoring large language models for superior performance on proprietary data and specialized tasks.

Building a structured, secure path to enterprise-wide Generative AI adoption.

Building specialized models where off-the-shelf solutions fall short.

Turning satellite and drone imagery into business intelligence.

Bringing the processing power directly to the data source.

Proactively reducing risks in hazardous industrial environments.

Understanding the movement and location of every item and asset.

Achieving super-human quality consistency on the production line.

Ensuring AI models are fair, compliant, and continuously performing as expected.

Designing infrastructure for instantaneous prediction on high-velocity streaming data.

Bringing inference closer to the data source for instant, offline decision-making.

Optimizing model hosting and resource management using cloud-native platforms.

Bridging the gap between the AI model and the enterprise application layer.

Automating the path from development to production for machine learning models.

Ensuring compliance, security, and sustained scaling of your digital workforce.

Automating customer and employee interactions using conversational AI.

Designing and implementing complex, automated end-to-end business workflows.

Turning unstructured content into structured, actionable data for automation.

Deploying a fleet of reliable software robots to execute manual tasks.

Identifying the highest-value automation opportunities for maximum returns.

Sustaining model performance and value over time in the real world.

Automating and managing the deployment of models as reliable services.

Ensuring model transparency, fairness, and compliance.

Building specialized models tailored precisely to your business needs.

Building high-quality, continuous data flow for machine learning models.

Defining high-ROI ML opportunities and a clear strategic roadmap.

Building the internal structure for BIM success.

The living model for optimizing building operations.

Linking accurate geometry to real-time budgetary information.

Visualizing the schedule to spot risks and optimize logistics.

Eliminating costly field errors before breaking ground.

Developing accurate, data-rich 3D models.

Centralizing models as the single source of truth for engineering projects.

Managing large-scale distributed infrastructure assets.

Optimizing product quality from design to customer use.

Training the next generation of safe, effective operators.

Virtual testing ground for optimization and expansion.

Enabling predictive, rather than reactive, maintenance.

Consistency, flexibility, and compliance for recipe-driven manufacturing.

The virtual environment for safe, risk-free process innovation.

Converting historical data into actionable, predictive insights.

The economic layer that delivers the highest possible profit.

Continuous health check and optimization of fundamental control loops.

Implementing dynamic, multi-variable control strategies.

Ensuring process safety and minimizing high-consequence risk.

Creating a single source of truth for all operational data.

Bridging the gap between operational data and enterprise IT.

Precision and speed for repetitive, high-volume tasks.

Centralized control and situational awareness for operators.

Foundation of robust and predictable operations.

Bridging the gap between engineering design and equipment supply, ensuring all procured items meet stringent technical and quality requirements.

Designing the critical layers of plant protection and communication systems required for emergency response and day-to-day coordination.

The backbone of the E&I system. Our meticulous cable design prevents interference and ensures accurate material procurement.

Precision instrument selection is key to reliable control. We ensure the right devices are chosen and sized correctly for all process applications.

Design and programming services for Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and critical Safety Instrumented Systems (SIS).

Comprehensive design for reliable power systems from substation interface down to the motor terminals.

Converting outdated or legacy plant drawings into accurate, digitized, and intelligent documentation essential for safe and efficient operations and future modifications.

The foundation of reliable piping. We develop, manage, and maintain comprehensive specifications to prevent material failure and ensure procurement accuracy.

Design of optimized pipe supports, from standard guides and anchors to complex special supports and dynamic restraints.

We build intelligent, data-rich 3D models that integrate piping with civil, mechanical, and E&I elements, eliminating field surprises.

Detailed flexibility analysis to ensure the integrity and reliability of critical piping systems under thermal, pressure, and external loads.

Full-scope detailing, spanning the entire lifecycle from preliminary layout to construction-ready fabrication packages.

Evaluating the structural fitness and remaining service life of aging or damaged equipment to determine safe operational limits.

Using industry-leading software like HTRI, Compress, and in-house tools to validate and optimize equipment performance based on process data.

The link between design and fabrication, providing clear, unambiguous instructions for construction and installation.

Ensuring piping systems are flexible enough to absorb thermal expansion and robust enough to handle all operating loads.

Expert guidance on specifying and procuring dynamic equipment critical to continuous plant operation.

Detailed calculation and drawing production for stationary equipment used in process plants, ensuring safe containment of fluids.

Beyond drawings, we provide the necessary documentation to guide procurement and construction, including technical specifications for concrete, steel, and site execution requirements.

We specialize in the complete design and detailing of Pre-Engineered Buildings (PEB) for industrial sheds and warehouses, as well as complex heavy structures like cooling towers, blast-resistant buildings, and machine bunkers.

We generate precise reinforcement plans for foundations, slabs, columns, and walls. Our focus on accurate Bar Bending Schedules (BBS) ensures compliance and reduces rebar waste.

Utilizing 3D modeling tools (Tekla), we produce precise drawings for every component, ensuring smooth fabrication and erection with reduced errors and site rework.

Our expertise covers design for all soil conditions and load types, including specialized design for dynamic loads from rotating machinery, and complex underground concrete infrastructure like pits and tunnels.

We perform load calculations (dead, live, wind, seismic), run detailed analysis models, and optimize the design of concrete and steel superstructures including pipe racks, platforms, and heavy equipment foundations.

We analyze existing facilities to identify constraints, recommend low-cost modifications, and implement advanced process control strategies to boost output and significantly reduce operational costs.

Ensuring the plant meets the highest safety standards through rigorous risk analysis, defining protective layers, and designing robust relief and flare systems.

We generate procurement-ready specifications by accurately sizing pumps, heat exchangers, vessels, and pipelines, ensuring optimal performance without over- or under-design.

The core of detailed design: creating intelligent P&IDs that accurately define all equipment, piping, instrumentation, control loops, and safety interlocks for the plant.

We leverage industry-standard tools (like Aspen Plus and HYSYS) to build models for both design optimization and operational troubleshooting, covering steady-state and dynamic behavior.

We provide the foundation for successful projects by evaluating multiple process schemes, performing site analysis, and establishing preliminary cost estimates (CAPEX/OPEX).

Maximizing performance while minimizing total ownership cost.

Bridging the gap between the digital design and the physical product.

Engineering profit into the core product design.

Ensuring product resilience and performance under stress.

Creating precise digital assets ready for production.

Defining the look, feel, and function of your new product.

Leveraging 3D printing for design freedom and supply chain flexibility.

Moving beyond reactive maintenance to true asset foresight.

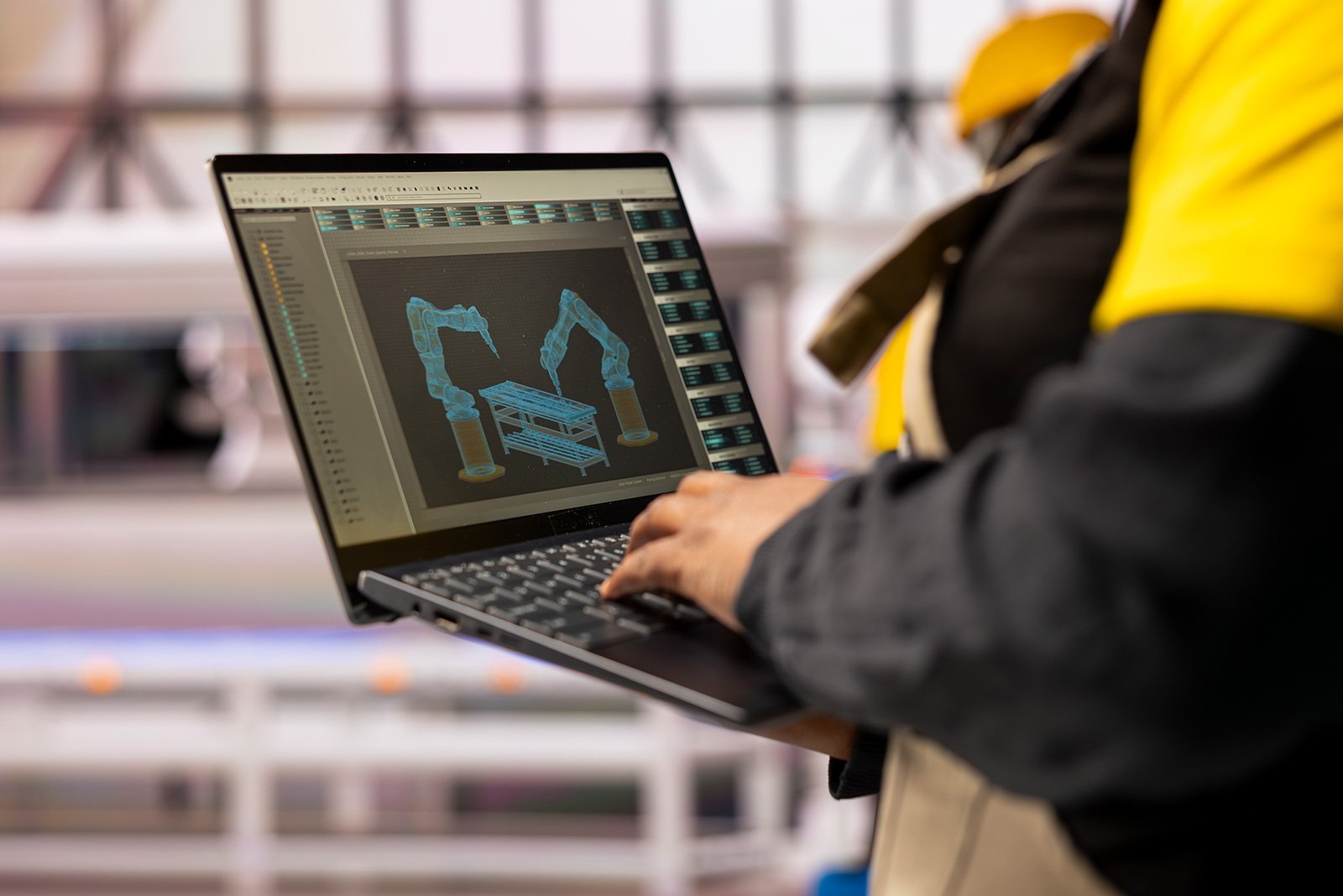

Testing and optimizing your factory in a risk-free virtual environment.

Designing high-speed, flexible, and safe robotic systems.

Connecting every machine and sensor for unified data streams.

Harmonizing enterprise planning with shop floor execution.

Bringing immediate intelligence and decision-making to the sensor.

Protecting the device, data, and cloud from compromise.

Managing, storing, and visualizing data from millions of devices.

Ensuring your devices talk securely and reliably.

Building the efficient, low-level software that runs the device.

Designing the physical brains of your connected device.

We leverage BIM to drive multi-disciplinary coordination by integrating architectural, structural, and MEP systems into a unified, BIM environment. Our approach goes far beyond basic 3D modelling, enabling clash detection, design validation, constructability and quantity forecasting.

Creating digital twins for existing (brownfield) assets and integrating historical maintenance and operational data

Physics-Based Simulation, Model-Based Systems Engineering (MBSE), IoT/Sensor Integration, Data Pipeline Engineering, Scenario Simulation & Optimization, Custom Application Development, Digital Twin Strategy, Legacy System Migration, Deployment and Support

Deploying advanced control strategies like APC and RTO, aided by process simulations, to maximize yield and energy efficiency.

System Design & Engineering, Conceptual & Detailed Design, Control Panel Design, Instrumentation Specification

Design of complete electrical systems including electrical equipment, JB, lighting, grounding, cable trays, and instrumentation to ensure safe, reliable, and efficient plant operation.

We design and optimize piping layouts with focus on constructability, accessibility, maintenance needs, and stress control ensuring safety, reliability and lifecycle performance. All designs adhere to international, European, German codes and standards such as ASME, API, ANSI, ISO, EN, PED and DIN.

We offer complete mechanical engineering services covering the specification, design, and validation of all critical static and rotating equipment. Our solutions ensure safe operation, high efficiency, and long-term reliability for all industrial sectors.

We deliver end-to-end civil and structural solutions to ensure plant infrastructure is safe, stable, and reliable. Our services include foundations, superstructures, equipment supports, and critical facilities vital for industrial performance.

We transform process concepts into safe, efficient, and commercially optimized designs. Our team combines deep domain expertise with advanced process engineering tools to deliver solutions that enhance plant performance, reliability, and long-term value.

Domain-aware specialists with transparent governance, KPIs, and clear value tracking across delivery models.

We operate with SRE practices, KPIs, and governance so your ERP stays reliable and efficient.

Real-time, role-based dashboards with governed metrics and drill-downs for action.

We de-risk transitions with architecture blueprints, pilot migrations, and reversible cutovers.

Tailored modules and extensions: approvals, pricing, quality, warehousing, or domain-specific workflows.

From requirement analysis to deployment, we orchestrate multi-domain rollouts with strong governance and change management.

Compliant, realistic data and right-sized environments that keep teams unblocked.

Production-grade telemetry with actionable runbooks and on‑call playbooks.

Stress your systems like production: scale, failover, and security controls verified pre‑release.

Automation that reduces flaky tests, speeds feedback, and increases coverage where it matters.

Platform engineering with golden paths, secure defaults, and developer self‑service.

Trunk-based development with multi-stage pipelines, ephemeral environments, and progressive delivery.

Quality engineered into every step — from unit to UX. Automation‑first, data‑driven, and CI/CD‑native.

Proactive, SRE‑informed application management that blends prevention with rapid response and continuous improvement.

Decompose monoliths into modular services with clear contracts, independent deployability, and strong observability.

Native and cross‑platform apps that feel effortless and work reliably in the field. Built with privacy, performance, and offline use in mind.

Modern web apps that are fast, accessible, and secure. Designed for real users and wired to your ecosystem with clean APIs.

We turn core systems into agile platforms that adapt to change. From ERP/CRM integration to legacy modernization, we simplify complexity so your teams focus on outcomes, not obstacles.

Turning insights into compelling narratives that drive organizational change.

Integrating advanced AI capabilities into your data ecosystem.

Moving beyond ‘what happened’ to ‘what will happen’ and ‘what should we do’.

Transforming complex data into intuitive, decision-driving visuals.

Unifying, cleansing, and preparing data for reliable, high-speed analysis.

Defining the roadmap for data-driven success and KPI alignment.

Bridging the gap between data engineering and machine learning model deployment.

Driving down compute costs and accelerating query response times for cloud analytics.

Building trust in data through continuous monitoring, validation, and error detection.

Building automated, scalable, and version-controlled data pipelines that adhere to DevOps principles.

Processing events instantly to power real-time dashboards and automated decision-making.

Designing the optimal cloud structure for speed, scalability, and cost efficiency.

Defining the human and process structure for sustained success.

Implementing perimeter and fine-grained controls to protect sensitive assets.

Creating the roadmap and dictionary for all your data assets.

Navigating complex privacy laws with a robust, auditable framework.

Implementing continuous quality assurance across all data pipelines.

Unifying core business data for consistent operations and reporting.

Operate networks with 24×7 monitoring, incident response, and continual improvement.

Full‑stack telemetry (flows, SNMP, synthetics, RUM) with AIOps to reduce MTTR and prevent incidents.

Standardize campus/branch with EVPN/VXLAN fabrics, NAC, and automation for repeatability.

Converged network & security with identity‑centric access and continuous verification.

Modernize Wi‑Fi with Wi‑Fi 6/6E, seamless roaming, and role‑based access for employees & guests.

Migrate from legacy WAN to SD‑WAN with policy‑driven routing, app‑aware QoS, and integrated security.

Cost transparency and governance with engineering and finance in the loop.

Robust lakehouse architectures with governance, lineage, and ML pipelines.

Composable services with functions, queues, and streams for elastic, cost‑efficient workloads.

Internal Developer Platforms (IDP) with golden paths for builds, deploys, and operations.

Factory approach with app discovery, wave planning, automated cutover, and risk controls.

Multi‑account architecture with security, identity, and network guardrails codified and enforced.

Design network slices and private 5G/LTE for high-availability enterprise workloads.

Use AI to predict traffic, detect anomalies, and plan capacity.

Modernize OSS/BSS to support converged services, dynamic pricing, and real-time charging.

Deploy MEC and IoT platforms at the edge for low-latency enterprise services.

Implement zero-touch provisioning and lifecycle management across multi-vendor networks.

Design and deploy cloud-native RAN and core using open standards.

Modernize and connect ERP, PLM, and manufacturing systems for synchronized design-to-build.

Automate inspection using computer vision and ML to detect defects inline.

Stand up a control tower for end-to-end supply chain transparency.

Create virtual replicas of assets, lines, or entire plants to test and optimize.

Deploy IoT and ML to monitor equipment condition and predict failures.

Upgrade MES and integrate SCADA/ERP layers to deliver live production insights.

Connect legacy enterprise systems with modern services using APIs and events.

Turn product telemetry and IoT data into commercial products and partner APIs.

Gain visibility into cloud spend and optimize without slowing teams.

Build MLOps pipelines and ship ML features into production apps.

Unify CI/CD, IaC, and security so teams ship fast and safely.

Architect and build software using microservices, containers, and serverless to reach global scale reliably.

Develop, validate, and connect regulated medical device software (SaMD).

Deliver secure virtual care and patient self-service experiences.

Automate and decentralize clinical trials to reduce time-to-insight.

Use AI/ML to augment diagnosis, stratify risk, and automate anomaly detection in medical imaging.

Connect EHR, LIS, RIS, pharmacy, and legacy systems with FHIR and modern integration patterns.

Build and migrate to HIPAA/GDPR-compliant cloud environments for PHI.

Secure financial workloads in the cloud with strong identity, encryption, and DR.

Digitize advisory, claims, and policy management flows.

Establish a secure, governed data layer for risk, growth, and regulatory workloads.

Automate AML/KYC, sanctions screening, and regulatory reporting with ML and RegTech.

Deliver seamless, mobile-first journeys for account opening, KYC, and loan approvals.

Plan and execute migrations from legacy core systems to modular, API-first platforms.

Modernize portals, usage visualization, and complex tariffs.

Protect OT and IT networks in line with sector regulations.

Equip field teams with data, mobility, and asset intelligence.

Turn AMI, SCADA, and field device data into reliable analytics.

Integrate DERs and optimize dispatch, while ensuring grid stability.

Deploy ADMS and related OT systems for real-time distribution management.

We automate checkout, fulfillment and cloud ops so teams can focus on growth.

We build secure, real-time data pipelines so business and CX teams can act faster.

We bring all your commerce channels to a single source of truth for inventory, orders, and customers.

We build headless, mobile-first frontends that are fast, SEO-friendly, and built for experimentation.

Embed AI into discovery and merchandising so every user gets relevant content and products.

We help you migrate from monolithic or stitched-together commerce platforms to a modern, API-first, headless stack.